BUILD SHIPYARD

NEW BUILDING SHIPYARD

NEW BUILDING SHIPYARD FACILITIES

- Total Area: 60.000m²

- Closed Area: 12.000m²

- Steel processing capacity: 20.000t

- New building capacity: 40.000DWT

- Maximum vessel size: 30.000DWT

- Slipways: 150m x 42m, 120m x 20m, 110m x 10m

- Cranes: 1x 100t, 1x 50t, 3x 15t, 5x 10t, 5x 10t

Equipment:

- CNC Plasma Cutting Machine 600 Ton

- Hydraulic Press 100 Ton

- Hydraulic Press Profile

- Bending Machine

- Welding Machines

- Electric Arc/Submerged/Inert Gas

WHY US

⦁ On-time Delivery,

⦁ Efficient – Proactive Planning System,

⦁ Determined And Committed Management Team,

⦁ Experience On Different Type of Vessels,

⦁ Dynamic, Eager and Open-minded Engineering & Technical Teams,

⦁ Qualified Workers, Technicians and Engineers,

⦁ Easy Accessibility to Advanced Sub-suppliers,

⦁ Cost Advantage, (due to order book)

⦁ Specialist Advisors for Sophisticated Turn-key Projects

SHIPYARD FACILITIES

- Total Area: 50.000m²

- Closed Area: 6.000m²

- Steel processing capacity: 5.000t/year

- Slipways: 150m x 50m ,130m x 33m

- Floating Dock: 184m x 27,2m

- TLC: 10.000T

- Hatch Cover Repair Area: 10.000m²

- Berthing Facilities: 1.000m (Without double berthing)

- Dock Cranes: 2 x 7,5t

- Mobile Crane: 2 pcs 35t

- Workshops: 6 x 200m²

- Steel Prefabrication Painting

- Blasting Pipe

- Outfitting Valve

- Hydraulic Shaft

- Propeller Electrical Machinery (for shaft pumps / coolers / heaters)

PRODUCTION RANGE

- Carbon Composite

- Steel

- Aluminum

- Steel + Aluminum

- Steel + Carbon Composite Segments

- Offshore Barges

- Fishing Vessels / Trawlers

- Passenger Vessels

- Chemical Tankers

- Search & Rescue Boats

- Carbon Composite Catamarans

- Fast Offshore Supply & Service Vessels

- R&D Projects

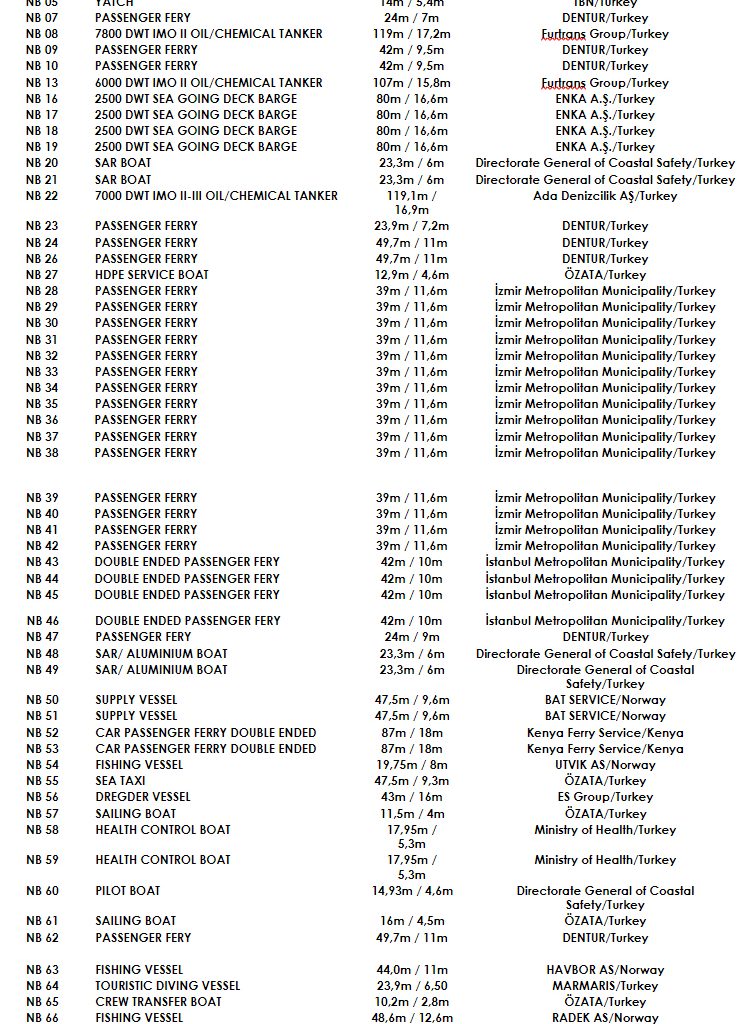

REFERENCE LIST

PRODUCTION SYSTEM

- Nesting, CNC cutting, bending, edge preparation works are carried out.

- Assembling of single parts.

- Merging of prefabrication products and single parts.

- Production of flat panels consisting of plate and profiles.

- Assembling of panels, components, prefabrication products and single parts.

- Production of units consisting of one or more sections. Before forwarding to slipway, this is the last stage to get into Paint Hallway.

- Specialized workers at individual work-stations

- Easier planning and better control of the activities

- Increased quality by simplifying the processes

- Reduction in movement of the workers and equipment, reduction in man-hours leading shorter delivery times