Bi-Axial pipes

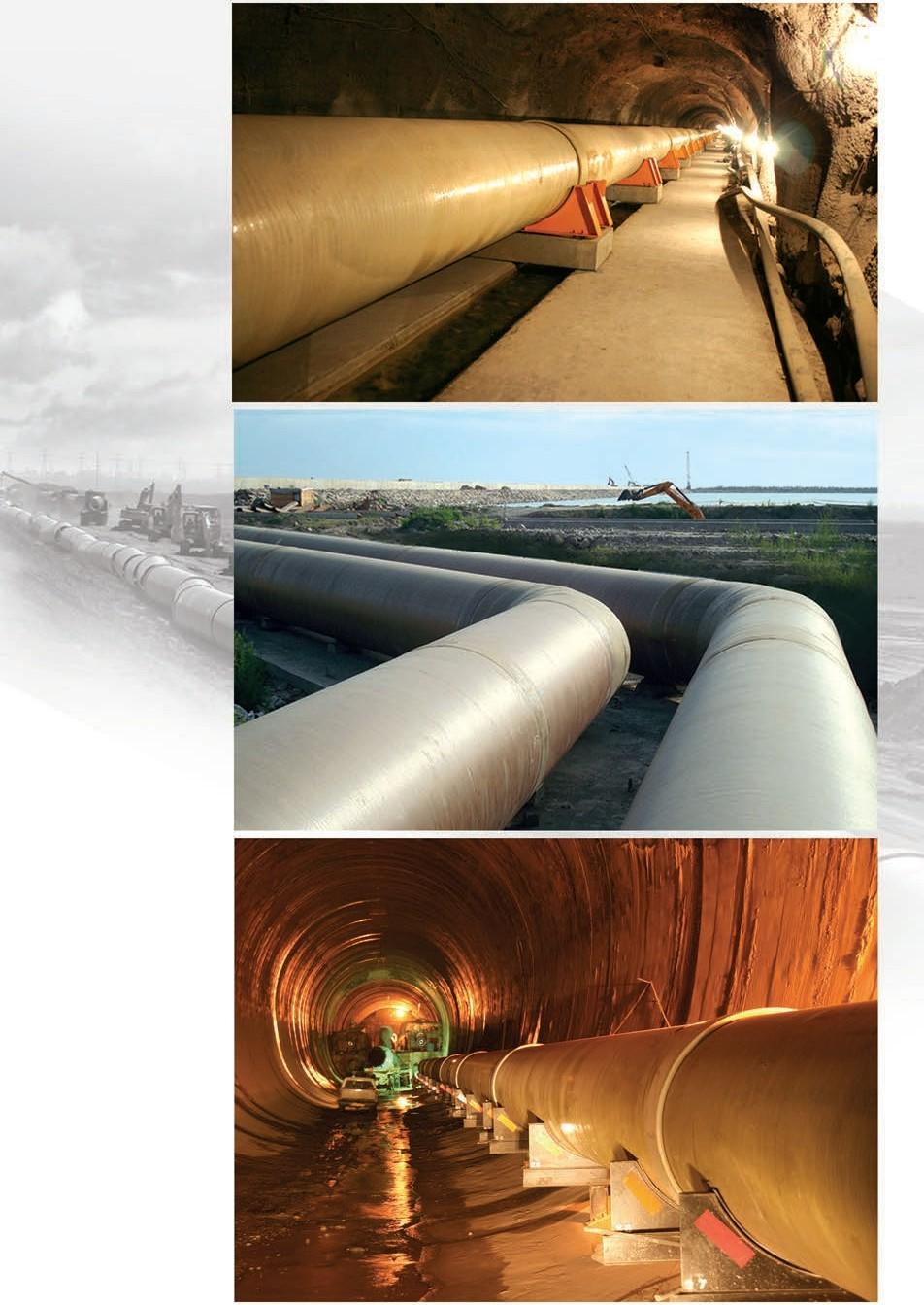

Bi-Axial pipes are well-designed GRP/GRE pipes which withstand full axial thrust as well as hoop stresses. Bi-Axial pipes provide high axial strength in both aboveground applications and crossing various natural features such as: rocky lands, rivers, loose soil, swampy and mountainous areas.

This type of pipes and fittings can also be produced to be fire-resistant.

Despite of some similarities between some of the Bi-Axial pipe specifications and those of Faratec Uni-Axial pipes, some of the Bi-Axial pipe advantages are presented as follows:

- High mechanical strength (even more than steel in hoop direction)

- High resistance against impact

- Installation in steep slopes

- Ability of the pipes to use rigid joints

- No need to thrust-block

- The best option for: loose soil, rocky land, mountainous areas, inlet and outlet headers or pipes for pumps and chambers

- constant roughness coefficient throughout the service life (like Uni-Axial pipes)

- Corrosion resistant (like Uni-Axial pipes)

- Low weight “being just 1/4 to 1/8 the weight of comparable steel pipe with the same diameter and working pressure” (like Uni-Axial pipes)

- Joinable to any other pipe types (like Uni-Axial pipes).

Bi-Axial pipes specifications

Faratec Bi-axial pipes can be manufactured up to 4000 mm diameter, 100 bar working pressure and 160°c working temperature based on customer‘s request.

Bi-Axial pipes are widely used in petroleum, petrochemical and water industries.

Bi-Axial pipes applications

- Petroleum fluids transmission

- Flammable fluids transmission

- Chemical fluids transmission

- Industrial sewage transmission

- Potable water transmission

- Urban sewage transmission

- Firefighting Networks

- Sea water transmission and etc.

Fittings

Different types of Bi-Axial fittings can be manufactured using either molded or mitered processes in our factory. All GRP fittings, such as elbows at various angles, tees, flanges, nozzles, etc. are produced in standard sizes.