Scope of pipes applications

Regarding to widespread applications of Faratec composite pipes, several examples on the applications are given as following:

- Water transmission and distribution (potable and raw water)

- Sanitary collection systems

- Storm sewers

- Sea water transmission systems

- Irrigation and drainage networks

- Cooling water systems

- Pipe jacking systems

- Hydropower plant projects

- Transmission of petroleum fluids such as gasoline, Fuel oil and etc.

- Sea-water transmission

- DM (demineralized) water transmission

- Potable water transmission

- Raw water transmission

- Urban sewerage systems

- Industrial wastewater systems.

- Utility piping

- Usage as casing

- Chemical fluids transmission pipeline and etc.

Performance of pipes in earthquakes

The effect of earthquake on buried pipelines is divided into two main categories of temporary land deformation due to the release of earthquake waves and permanent land deformation such as liquefaction, lateral extension and landslide. During design and routing of pipelines, geotechnical studies should identify the geological hazards associated with earthquakes, in order to select the most suitable route for pipelines.

The experience of extreme earthquakes in different parts of the world has indicated that composite pipes have the ability to function properly.

This appropriate behavior in the earthquake is due to the following three factors:

1- The considerable flexibility of the fiberglass pipes and the matching of the pipeline with temporary and permanent deformation of the earth during and after the earthquake.

2- High mechanical strength of the fiberglass pipes allows the pipes to tolerate stresses from the surrounding soil.

3- Joint s of fiberglass pipes have a good functionality against earthquakes. The common REKA coupling joints with an axial tolerance of at least 0.3% length and a suitable deflection angle, can depreciate a significant portion of the deformations on the pipe. On the other hand, rigid joints such as glued coupling or lamination joints have the ability to attach pipes to create continuous operation in the pipeline and stress is tolerated by the pipe body.

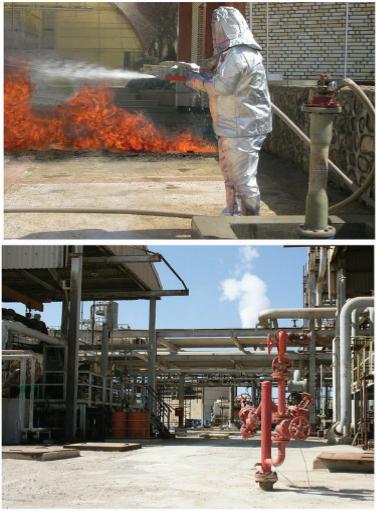

Fire retardant pipes

This class of pipe can withstand external fire temperature up to 1100 °C from direct propane flame for 30 minutes. Final temperature of inside running fluid will be less than 50°C after the test (30 minutes). In addition, no problem or leak will be occurred when the test is finished.

Resistance against abrasion

Faratec pipes are abrasion resistant. The abrasion resistance coefficient can predict the effect of sand or other particles on the inner surface of the pipe. Faratec pipe resistance has been investigated by the Darmstadt rocker method.

Chemical fluids transmission

Faratec pipes can be used in order to transfer different Chemical fluids, changing glass fibers and resin type as well as manufacturing process.

Qualification for the transfer of drinking water

Faratec composite pipes have been tested and approved for drinking water transmission by Ministry of Health and Medical Education of Iran and the WRAS Institute of England.

Other applications and advantages

Application of the products is not limited to pipelines. The headers of cooling towers and also water distribution system of cooling towers is manufactured as industrial applications of the Faratec pipes.

Since Faratec pipes provide resistance against corrosion and scaling and they have constant smooth inner surface, these pipes are the best options for water distribution system of cooling towers.